Hardware - Rocket

So, my son John is away at school studying Aerospace Engineering, and one day he calls me up all excited and says, "Dad, I want spice up my resume. Let's build a rocket! You know; not just some glorified bottle-rocket; I mean let's build a high-power rocket; I want that thing to go so high that it'll see the sky go black! So, what do you know about rockets, dad?"

Thus began our rocket project.

We decided, "Heck! How hard could it be? It's just physics. Sheesh! We know physics as well as those guys down at NASA. We can build a rocket just like NASA. We don't have to be NASA to make spectacular fiery explosions like them. NASA, SHMASA; big deal!"

So we called our enterprise SHMASA, and we named our rocket, Black Sky.

Details

Our Pulse-Jet Rocket project has been a fun research and development project from the beginning. We’ve been planning all of the aspects of it, but we have only built and tested the engine components so far. John conceived the idea, and built the engine hardware, and I have worked mostly on the fuel and electronics stuff.

Our first objective was just to get the dumb thing to run. This kind of engine is "supposed" to be easy to "build and start"; but we found the devil was in the detail. Sure it would be fairly easy to build another one that would start right up, but only because we discovered all the millions of details that are absolutely essential. In other words; imagine trying to fabricate an automobile engine (including the camshaft and carburetor) from raw materials using only very general dimensions (without any detailed specs); designing and building by intuition and your own research. Oh, chugging and blowing smoke is better than nothing, but you wouldn’t have it ready for a car show or the race track without a lot of work and time. Well, because aesthetics is important to us, and performance is critical; our development project has been long and meticulous, and full of discoveries: both constructive and destructive.

The Team

We've completely engulfed the test stand in flame, but surprisingly we haven’t had any problems with the 2x4's, although the setup has evolved somewhat over time.

According to published dimensions, we should be able to produce a suitable thrust from our size engine, but for quite a while all we got were some spectacular "pop"s.

Propane Test Fire

We concluded the first problem was that the fuel was just squirting in a line, so it probably wasn't getting mixed very well. We spend a lot of time and effort devising tests to determine exactly what was going on. We were certain the fuel nozzle was a problem.

Don’t worry, all the photos of fuel nozzle spray tests were using water instead of a fuel.

Fuel Nozzle Test 1

So we created a baffle that dispersed the fuel rather than just have it squirt down the barrel. That did the trick and we got our first actual engine run. It lasted for 45 seconds or so, but it seemed to sound like it had a good steady thrust. After it died we did an autopsy on it and found the intake head had suffered some serious burn damage.

This picture shows the assembly of valve retainers, warped flapper-valves, and a seriously melted valve seat.

Heat Concentration Problem

We decided the baffle thing was the problem, and we needed to disperse the fuel better right from the nozzle. We tried to fabricate spray nozzles, but concluded we couldn’t do a very good job of it with hand tools.

Fuel Nozzle Test 2

We were thrilled to find a supplier that made just what we needed.

Fuel Nozzle Test 3

We tried an open flame test to see just how big a flame we were producing inside the engine. We were concerned about fuel pressure, because it didn’t seem like the flame (or popping or engine running) was at all proportional to the fuel pressure. We tried running the propane in both a gaseous and liquid state, and it was simply indeterminable. We decided it must be experiencing some sort of vapor-lock.

Propane Flame Test

We fabricated a pressurized fuel tank and tried using gasoline instead of propane. The difference was dramatic so say the least. This test says nothing of pressure or the dynamics inside the combustion chamber, but we confirmed our research that gas had a lot more potential energy per unit mass than LPG.

Gasoline Flame Test

We found that we had to use a much finer mist spray nozzle for the gasoline, so the fuel completely burned, and so we could keep the fuel flow low enough that we weren’t completely drowning the engine (and engulfing the whole thing in flame). We figured that liquid gas falling burning to the ground was probably a bad thing - ya think?.

We tried several configurations at different fuel pressures and valve tensions, and all the other variables we could think of.

Fuel Nozzle Arrangement

Fuel Nozzle Spray Test

The Gas fire pops were certainly much more energetic than the LPG.

Gasoline Test Fire

Our fuel manifold has evolved into quite a clean and robust configuration; as has the rest of the whole engine head. We needed to be able to rapidly take it apart and change the various components for multiple tests, so got to be pretty good at it with so much practice.

We also added some electronic instrumentation: a load cell to measure the thrust, and pressure gauges to measure the fuel pressure and the combustion chamber pressure.

Fuel Manifold and Instrumentation

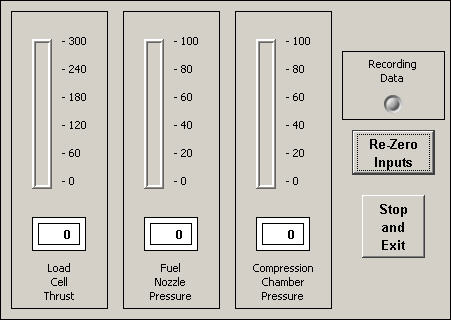

I got an inexpensive DAQ unit (a DataQ DI-148U) and reprogrammed the whole interface to sample several hundred data points per second so we could actually watch the pulse dynamics.

The Test Setup

The DAQ driver is written in C, and the user interface is written in Java. All the data is stored in an Excel file so we can easily chart and analyze it in detail after the fact.

Instrumentation Display

We are already working on our second generation engine with a whole myriad of improvements based on our research and development so far.

[editorial note a couple years later… John was so busy finishing up his degree that we thought it would be best if we put the whole rocket activity on a low-boil until he finishes – he was spending a LOT of his time on this (as was I) and I’d hate to see his grades would suffer because of our hobby project – we continued working on it, just not at as brisk a pace as before.]